The CEMB-SM1100 is a powerful and efficient tire changer and balancer machine that revolutionizes the way you handle tire services. Designed with cutting-edge technology, it provides precise performance, making tire installation and balancing tasks faster and easier than ever before. MSRP: $30,177 -> Now just: $15,250!

Professional Service Network Quarter 3 2024 Rebate Offers

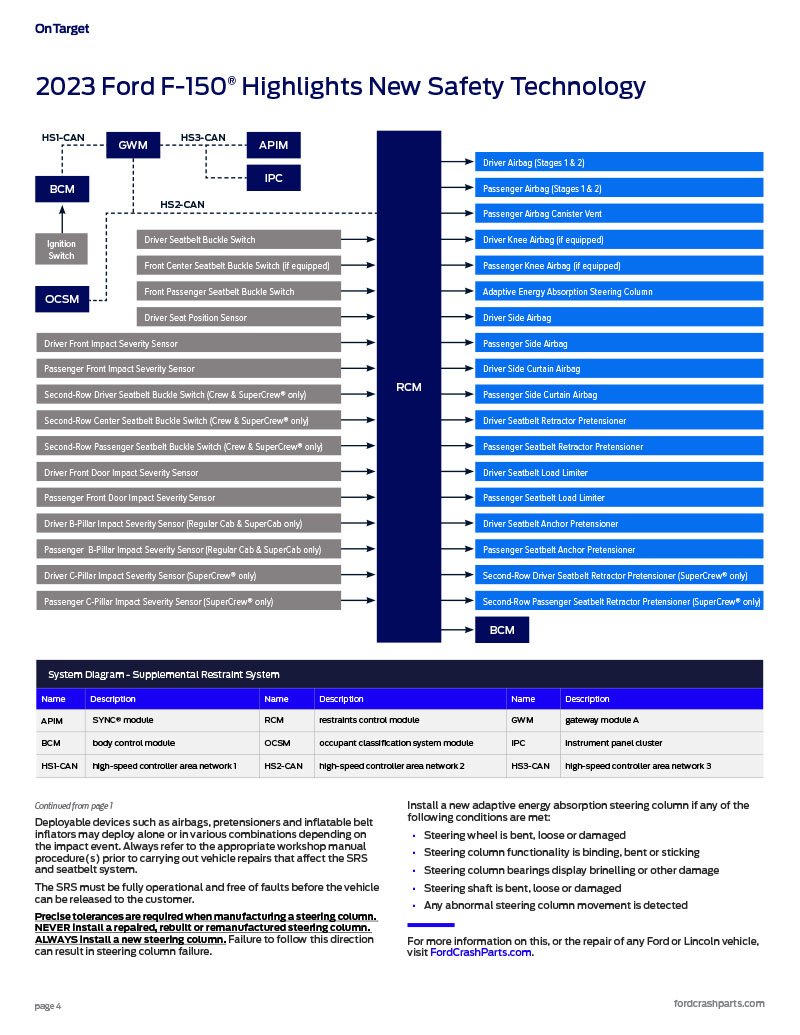

Ford On Target 2023, Volume 4: Ford F-150® Highlights New Safety Technology

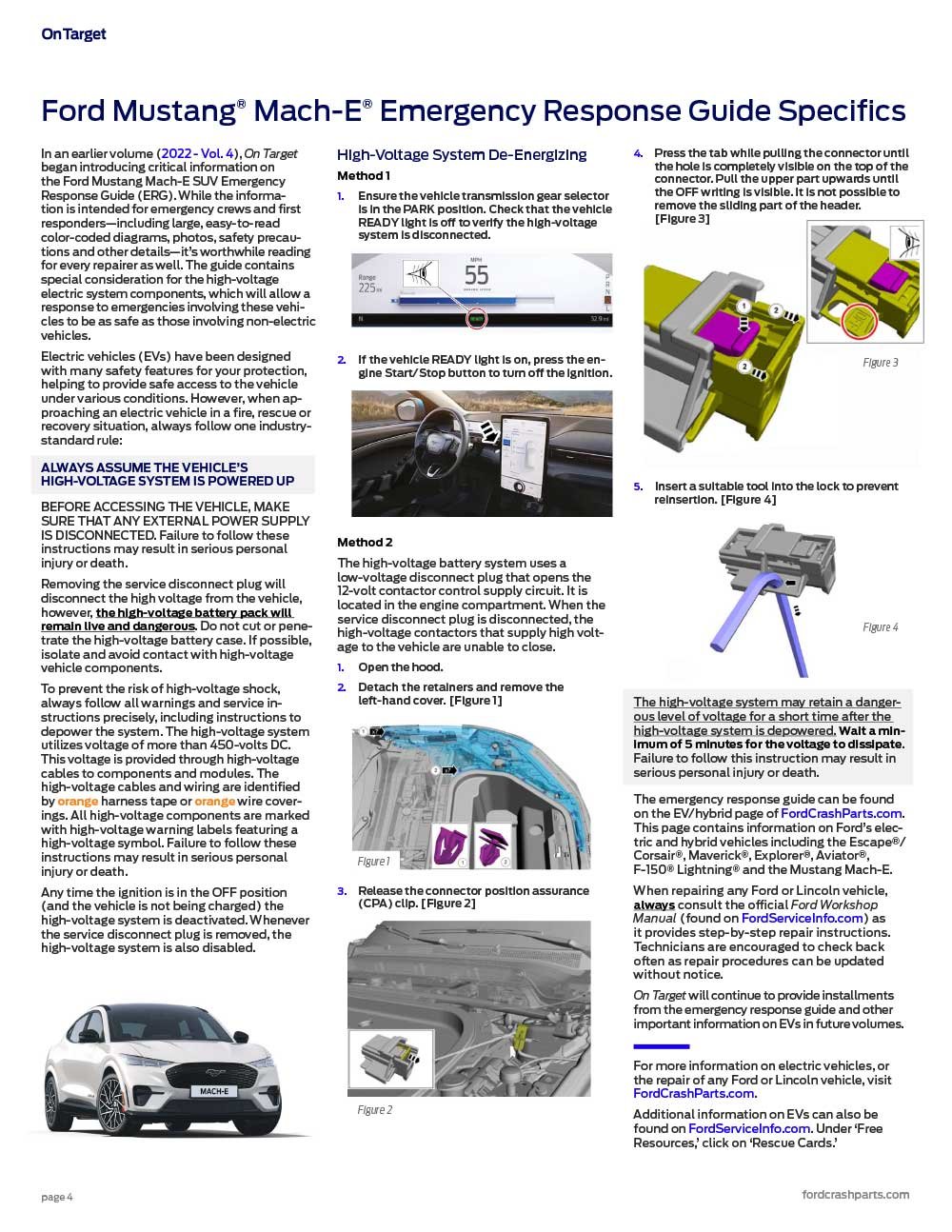

Here is the newest issue of the On Target magazine from Ford Motor Company.

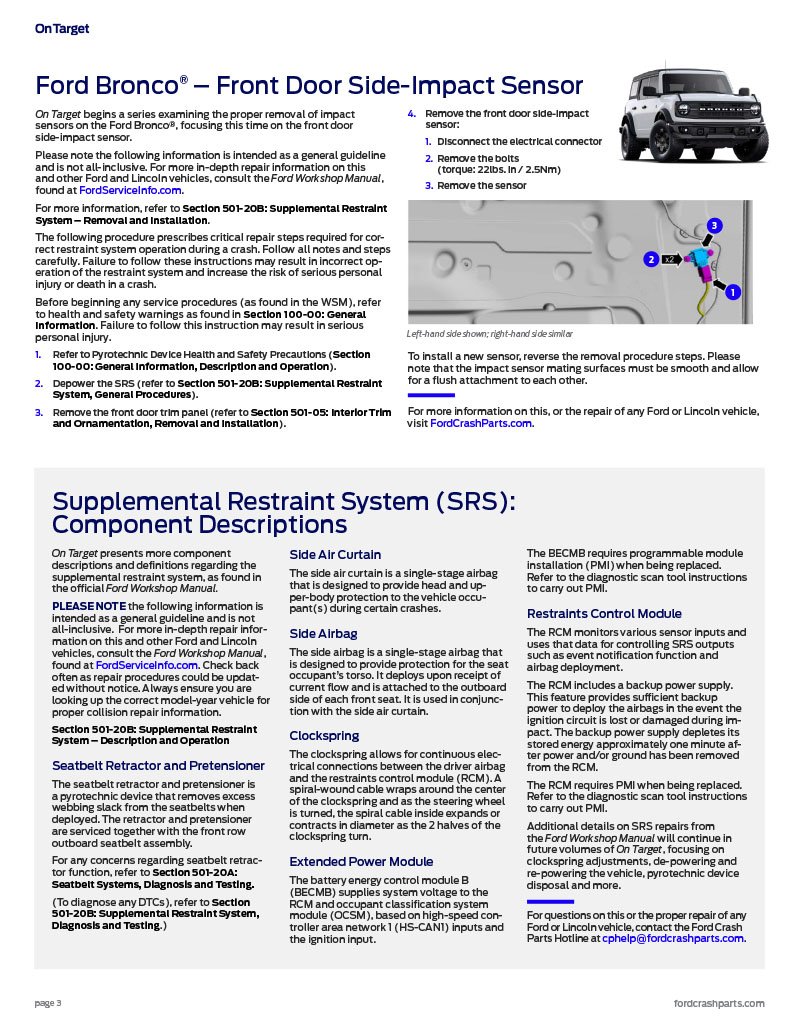

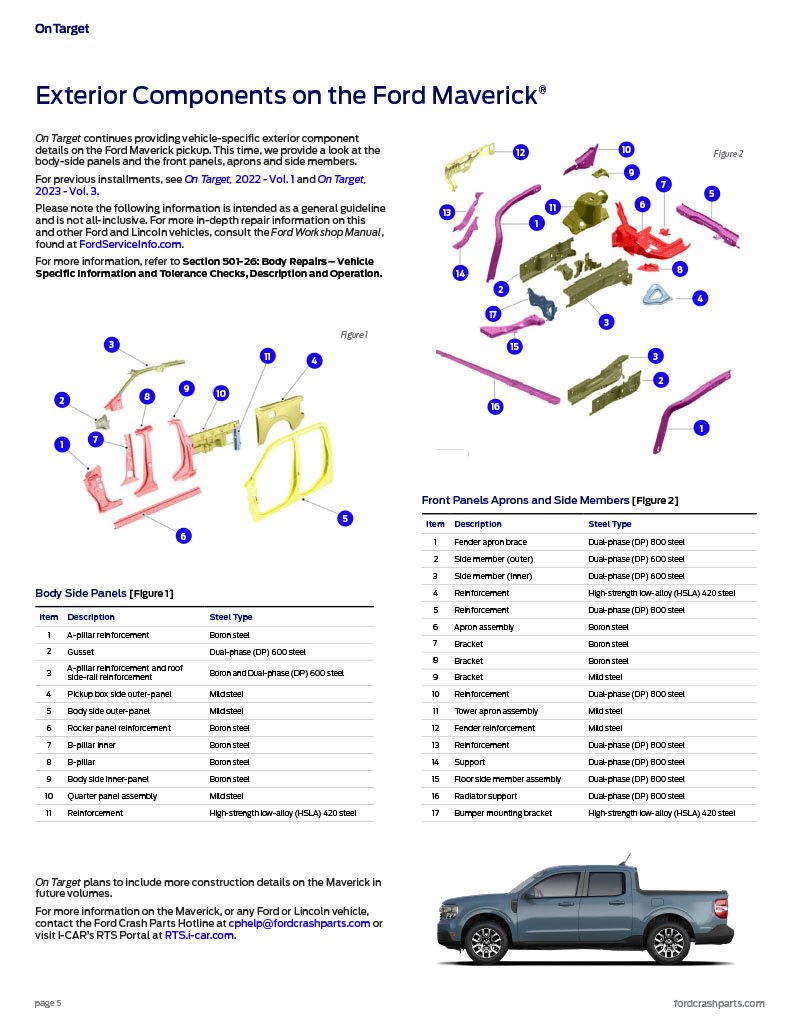

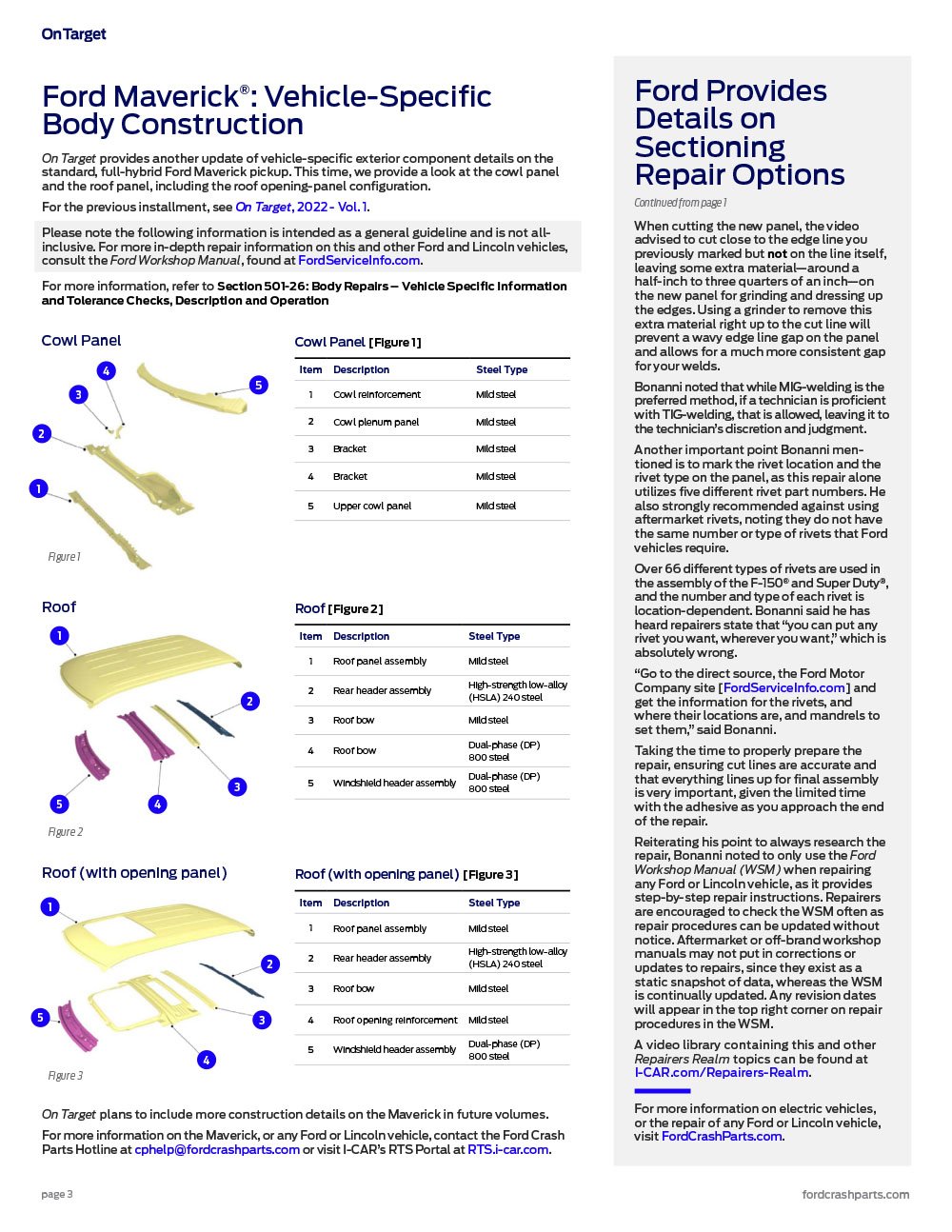

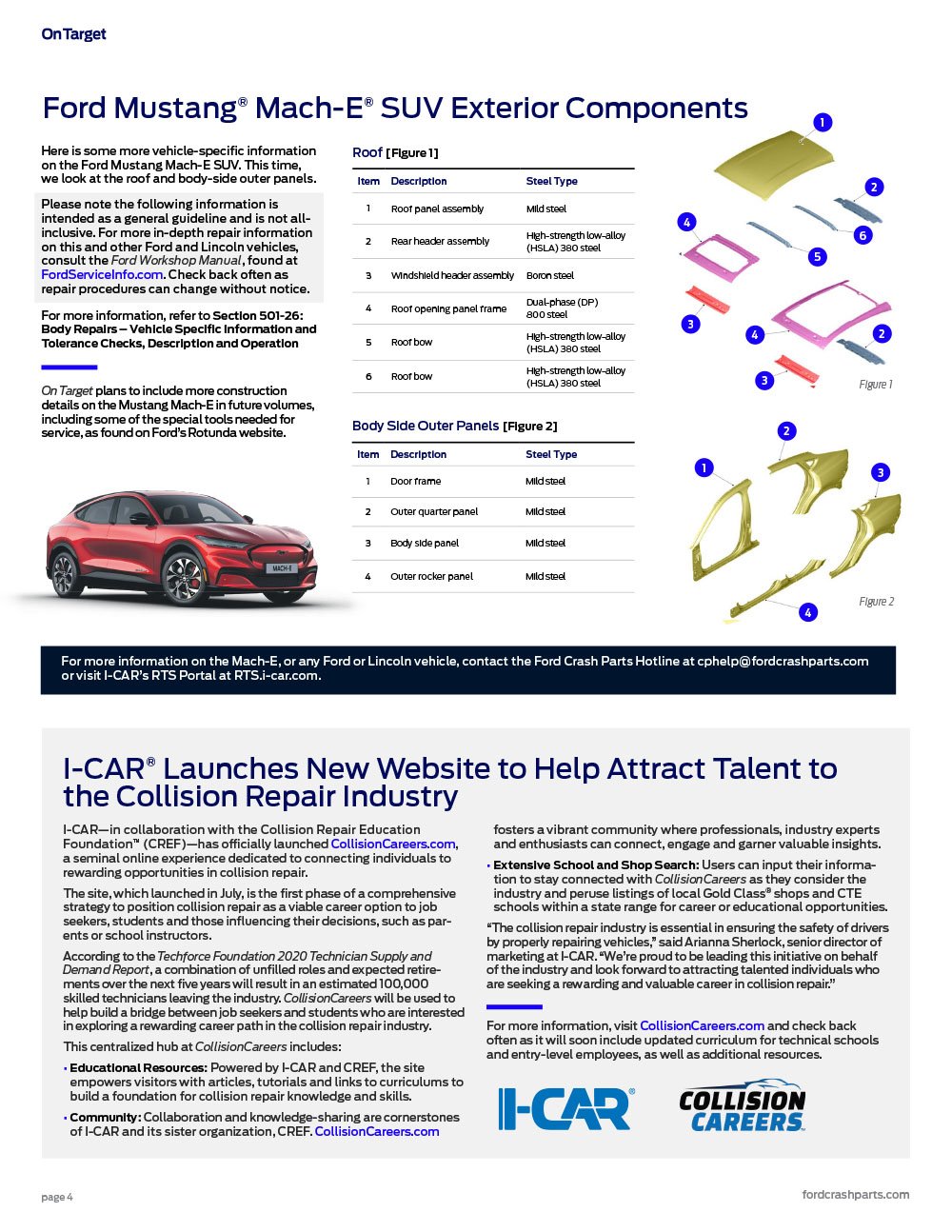

In it, you will find a wealth of collision repair material including details on the adaptive energy-absorption steering column; more tips and tricks on sectioning procedures directly from Ford and I-CAR®; vehicle-specific information on the Ford Maverick®; side-impact sensor repairs featuring the Ford Bronco®; 2023 in review; OEM glass information; and much more!

Audi Technical Service Bulletin: Headlamp Condensation

Please take a moment and read this very important Audi Bulletin regarding moisture in headlights.

Click on the button below to download the full document.

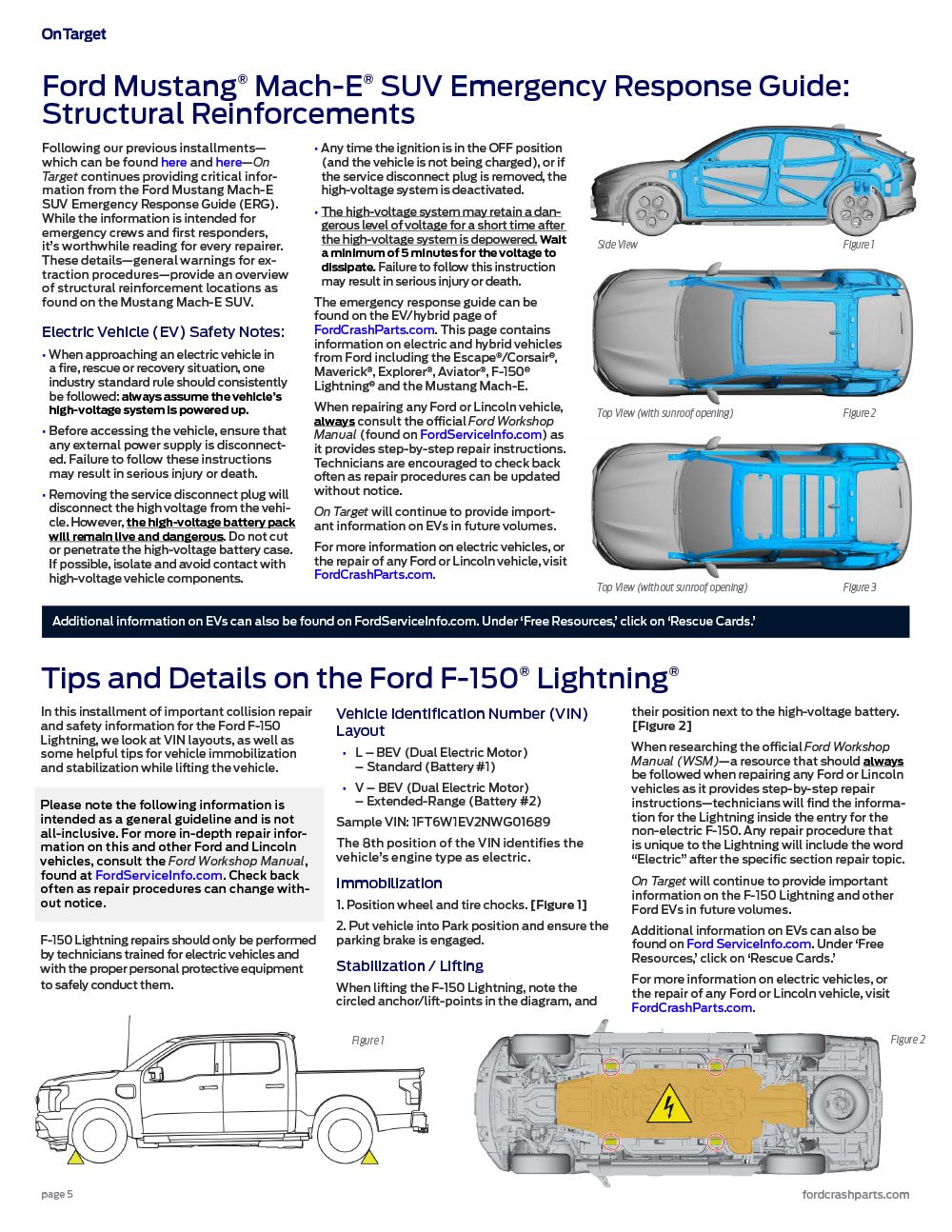

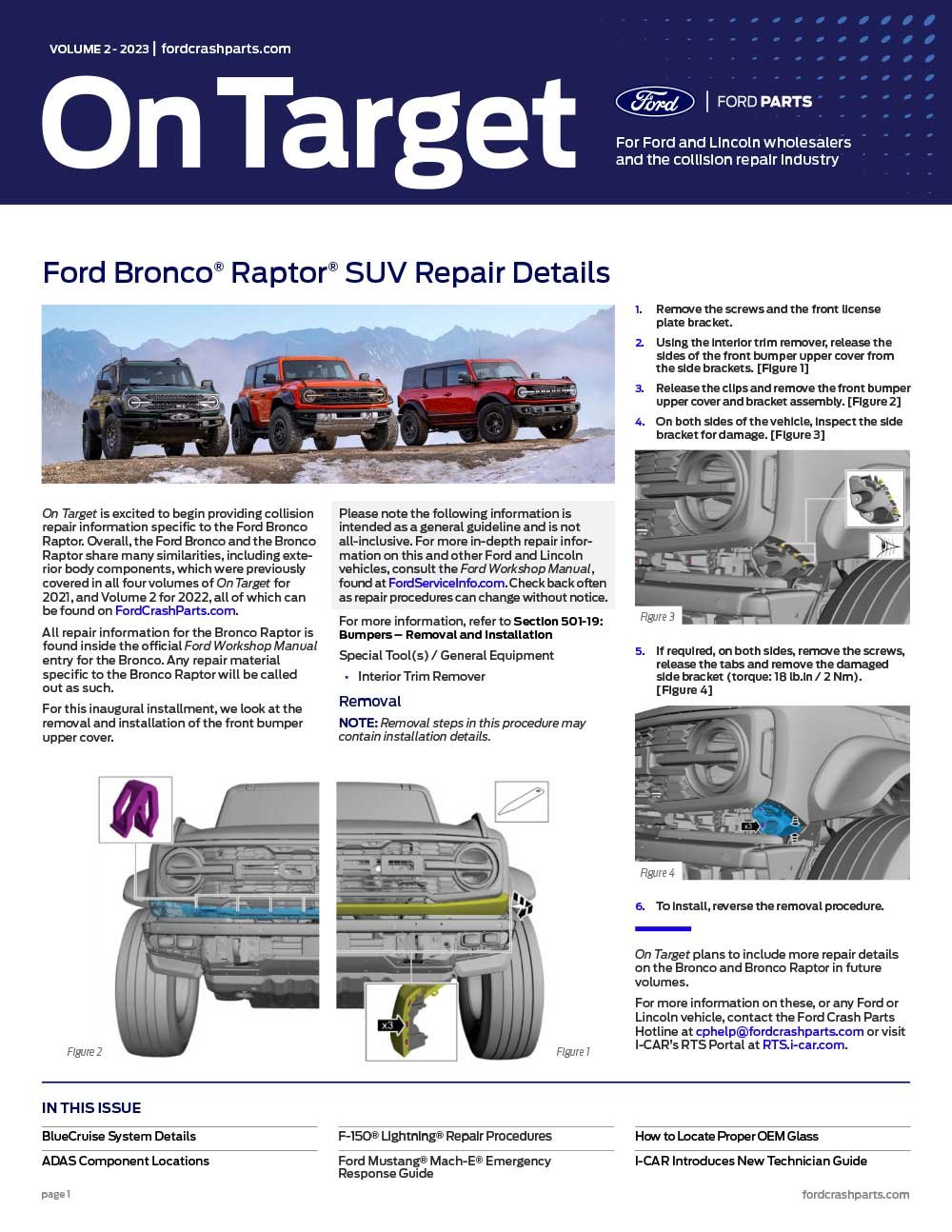

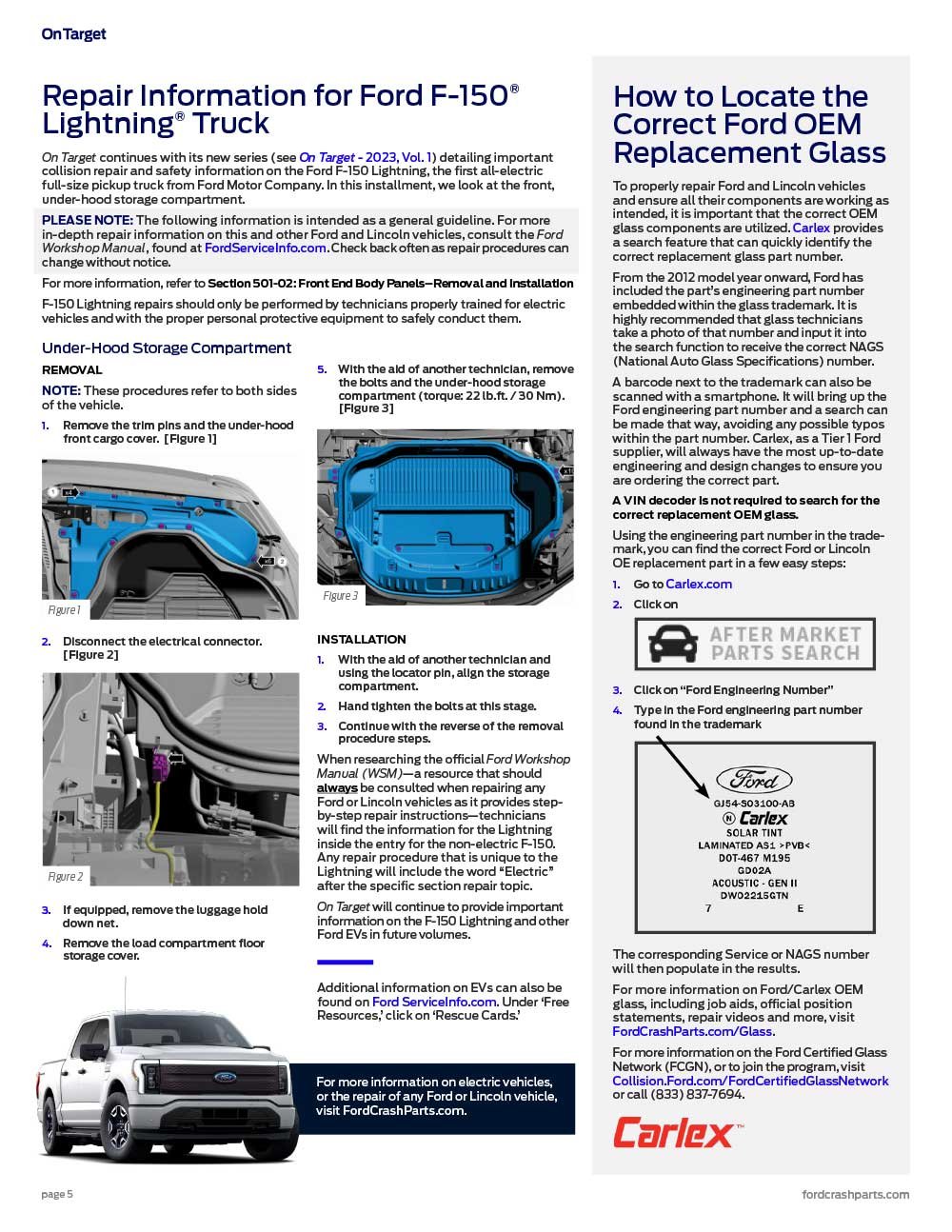

Ford On Target 2023, Volume 3: Collision Repair Newsletter

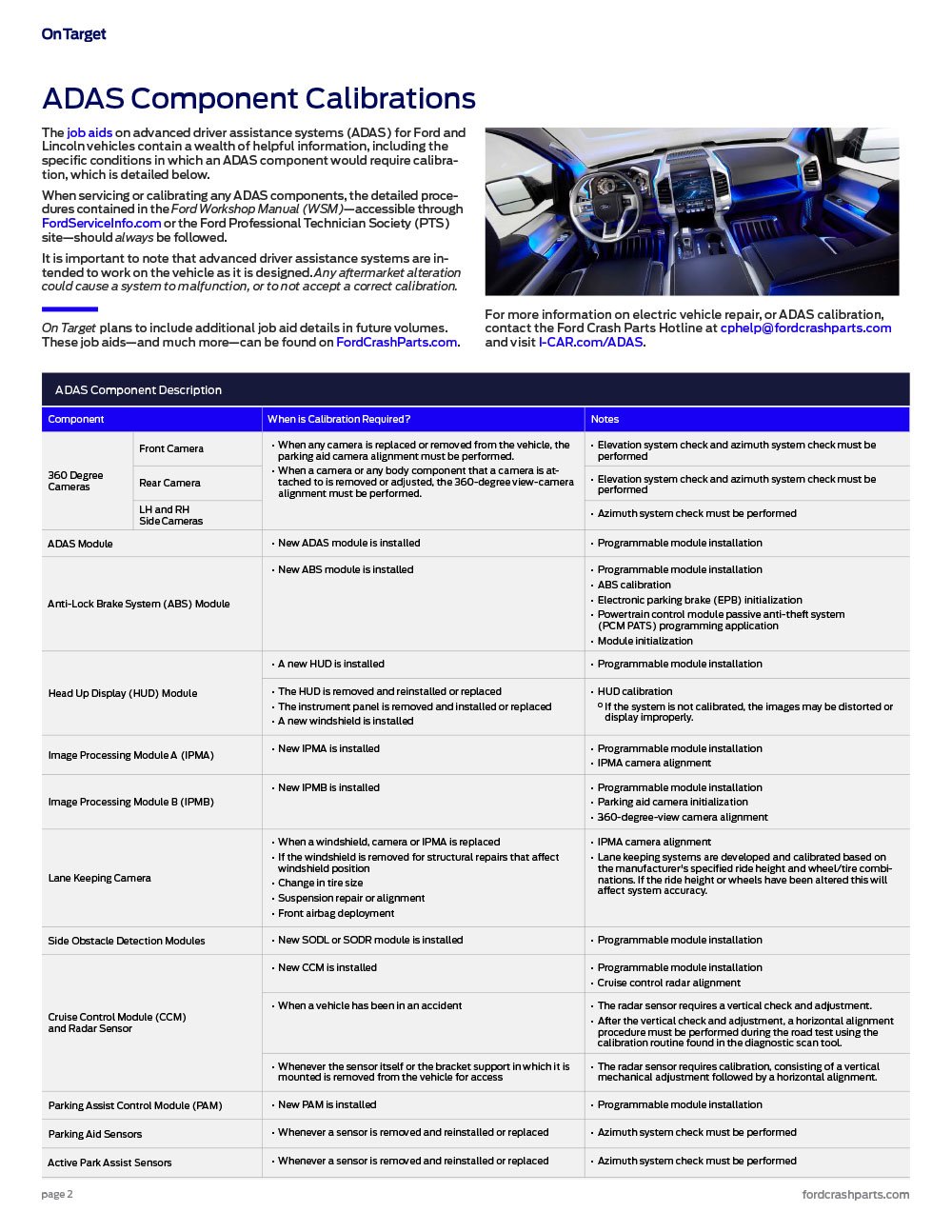

Ford Provides Details on Sectioning Repair Options

Researching collision repair procedures and mapping out a full repair plan before work begins is not only a great rule of thumb and a good foundation to providing a proper repair, but it is also the key piece of advice that Gerry Bonanni, senior damageability engineer for Ford Motor Company, has always stood by.

“Researching the repair ahead of time will make for a much more efficient repair. There is a huge benefit to knowing what you need to do ahead of time and taking the time to do it right,” said Bonanni.

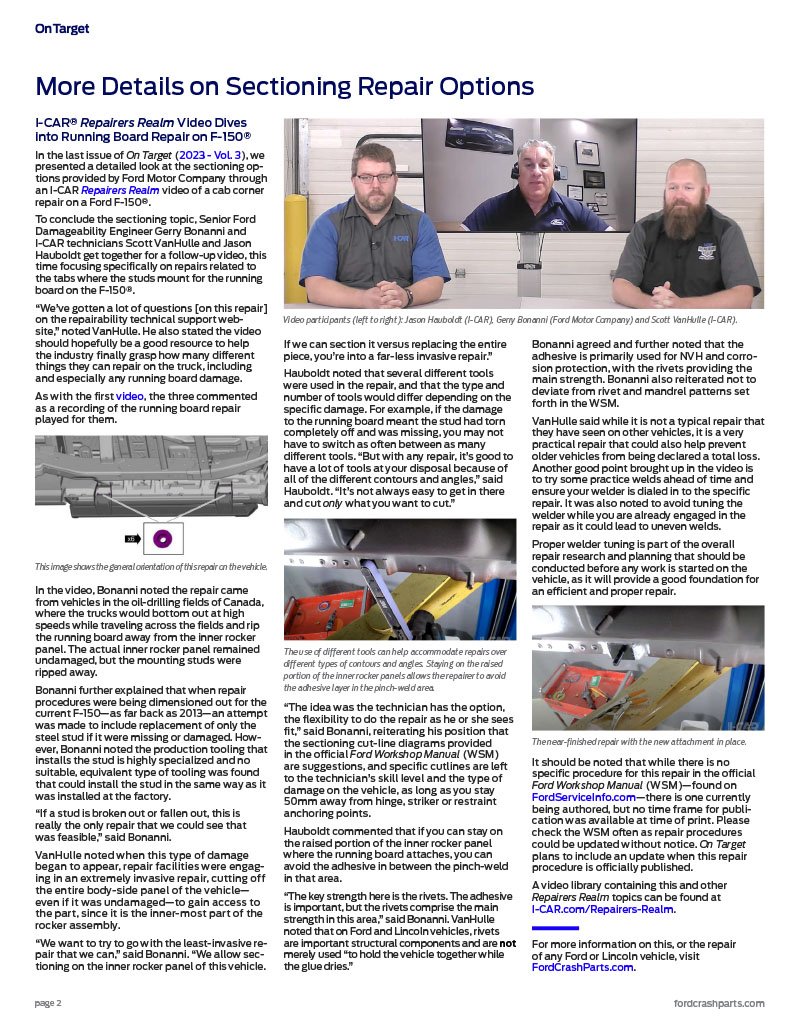

Gerry Bonanni, Senior Engineer Bonanni reiterated that position in his recent appearance in an episode of I-CAR®’s Repairers Realm video series, where he joined I-CAR technicians Scott VanHulle and Jason Hauboldt to discuss Ford sectioning options, using a pre-recorded video of a cab corner repair on a Ford F-150®.

The video noted the first step of the repair is to prepare the vehicle, which includes protecting elements of the vehicle not included in the repair, such as the fixed glass. The discussion then focused on the best places to cut to section.

“It’s important to note that the sectioning cut-lines provided in the of-ficial Ford Workshop Manual are suggestions,” said Bonanni. “As long as you stay 50 millimeters away from striker or hinge points, which is an industry standard, the best place to cut on exterior components is left up to the technician’s skill level and the type of damage on the vehicle.”

The video points out that drilling rivets to remove them is not easy and that pressing them out with proper, Ford-approved tools—such as a self-piercing rivet (SPR) gun—works better. Another tip provided when using an SPR gun is to ensure it is flush against the rivet, and to not angle it or force it into position as it could snap the die. [Download to Read More]

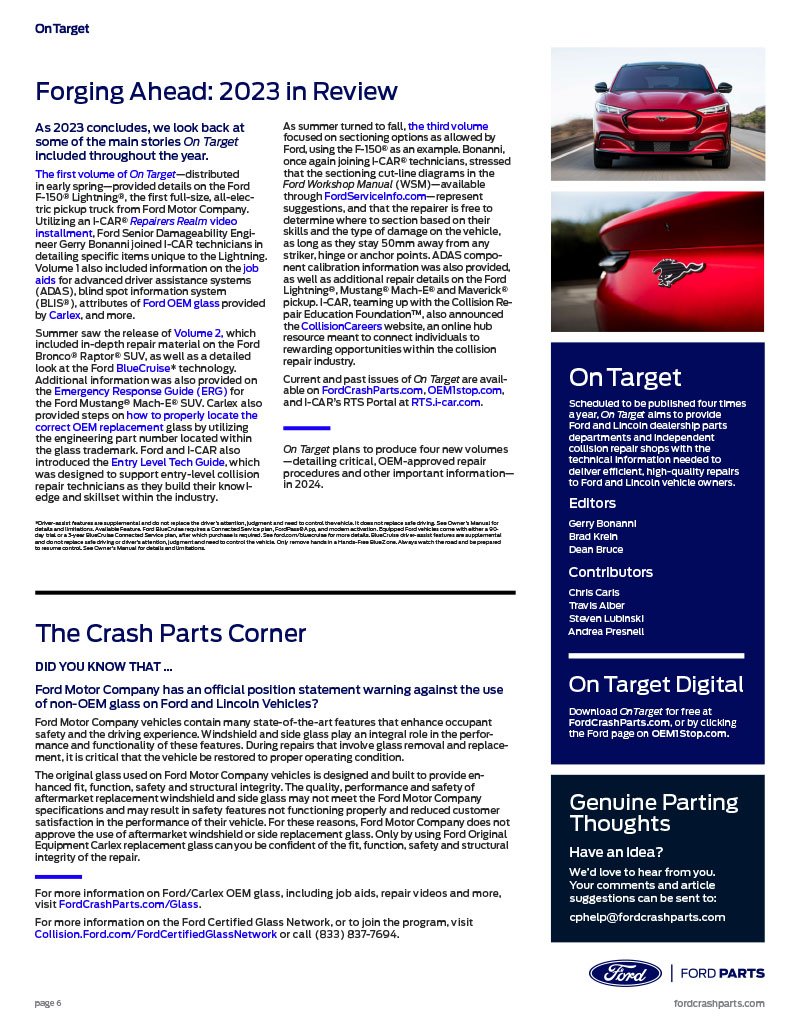

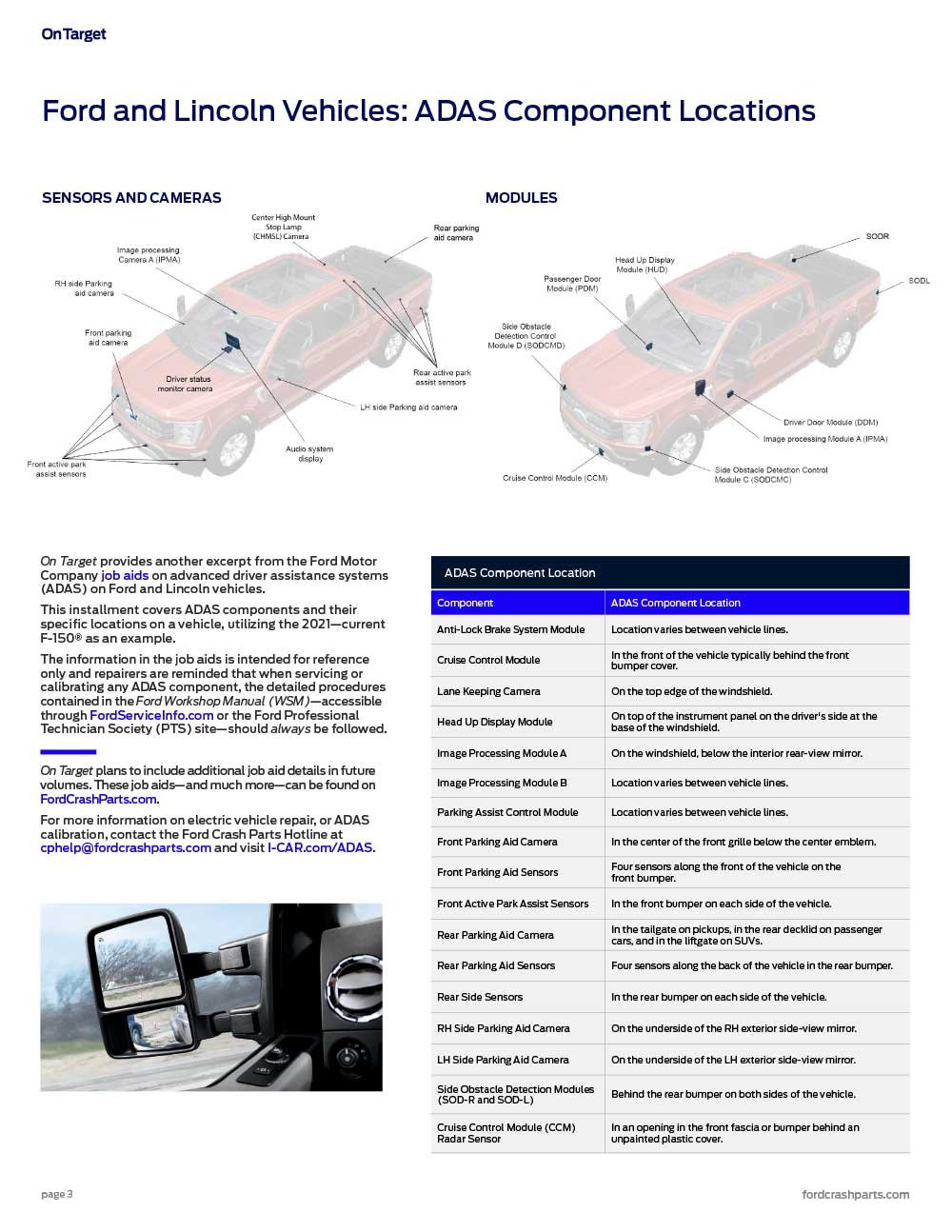

ADAS Component Calibrations

The job aids on advanced driver assistance systems (ADAS) for Ford and Lincoln vehicles contain a wealth of helpful information, including the specific conditions in which an ADAS component would require calibration, which is detailed below.

When servicing or calibrating any ADAS components, the detailed procedures contained in the Ford Workshop Manual (WSM)—accessible through FordServiceInfo.com or the Ford Professional Technician Society (PTS) site—should always be followed.

It is important to note that advanced driver assistance systems are intended to work on the vehicle as it is designed. Any aftermarket alteration could cause a system to malfunction, or to not accept a correct calibration. [Download to Read More]

The Crash Parts Corner

DID YOU KNOW THAT…

A recent I-CAR® Repairers Realm video covered the importance of OEM replacement glass components, as well as the proper tools, equipment and procedures for installing them?

The video—which can also be found at FordCrashParts.com—was hosted by I-CAR technicians Scott VanHulle and Scott Kaboos, who welcomed glass experts from various automakers, including Tim Siterlet, Regional Sales Manager for Carlex Glass America, LLC, the manufacturer and distributor of OEM replacement glass for Ford and Lincoln vehicles.

“Glass has evolved technologically,” said Siterlet, when asked why OEM glass is such a big deal. “OEM parts are designed and engineered, manufactured and tested to the highest quality, government standards. In fact, OE parts must also meet additional federal motor vehicle safety standards. Today’s original equipment glass are performance parts for the vehicle. They enhance your driving experience, your comfort levels and can increase the safe levels of operation when combined with the advanced driver assist features.”

Siterlet noted that many, if not all, glass components are patent-protected, meaning that none of the important vehicle-specific part information—including optical quality, curvature, shape, thickness and other details—are shared with the aftermarket. [Download to Read More]

INFINITI Collision Parts Rebate Program

Ford On Target 2023, Volume 2: Collision Repair Newsletter

ACDelco Training Course Catalog | GM Genuine Parts

Save on Genuine Audi Parts with CCC One

Mercedes-Benz StarRewards Program

The StarRewards program is an easy way for your business to earn valuable rebates for purchasing Genuine Mercedes-Benz Parts from an authorized Mercedes-Benz dealership.

INFINITI Maintenance Advantage Parts

Designed for today’s competitive market, Maintenance Advantage ® parts offer INFINITI-validated fit and performance at affordable prices.; Maintenance Advantage ® offers a broad line of brake rotors/pads, spark plugs, air filters, radiators, condensers, and wiper blades.; Maintenance Advantage ® now offers over 90 pad applications and over 80 rotor applications.

Friction Friday: DFC 5000 Brake Pads

Today, vehicles are increasingly more sophisticated. These vehicles demand the absolute highest quality and performance from their individual components, driven by the move towards autonomous mobility. With this change, the individual components in all the systems need to interact with one another, each depending on…

Quality-Built Brake Calipers

“Honest Product, Honest Answers” - A Commitment to People from DFC

Co-Founder Dino Crescentini highlights our commitment to people, starting with our DFC Customer Support Team, and extending all the way to the Customer’s Experience.

At DFC, people are “our most valuable asset.”

We’ve gone above and beyond to create a best-in-class Customer Support Team, capable of handling any challenge that comes our way. DFC is committed to…

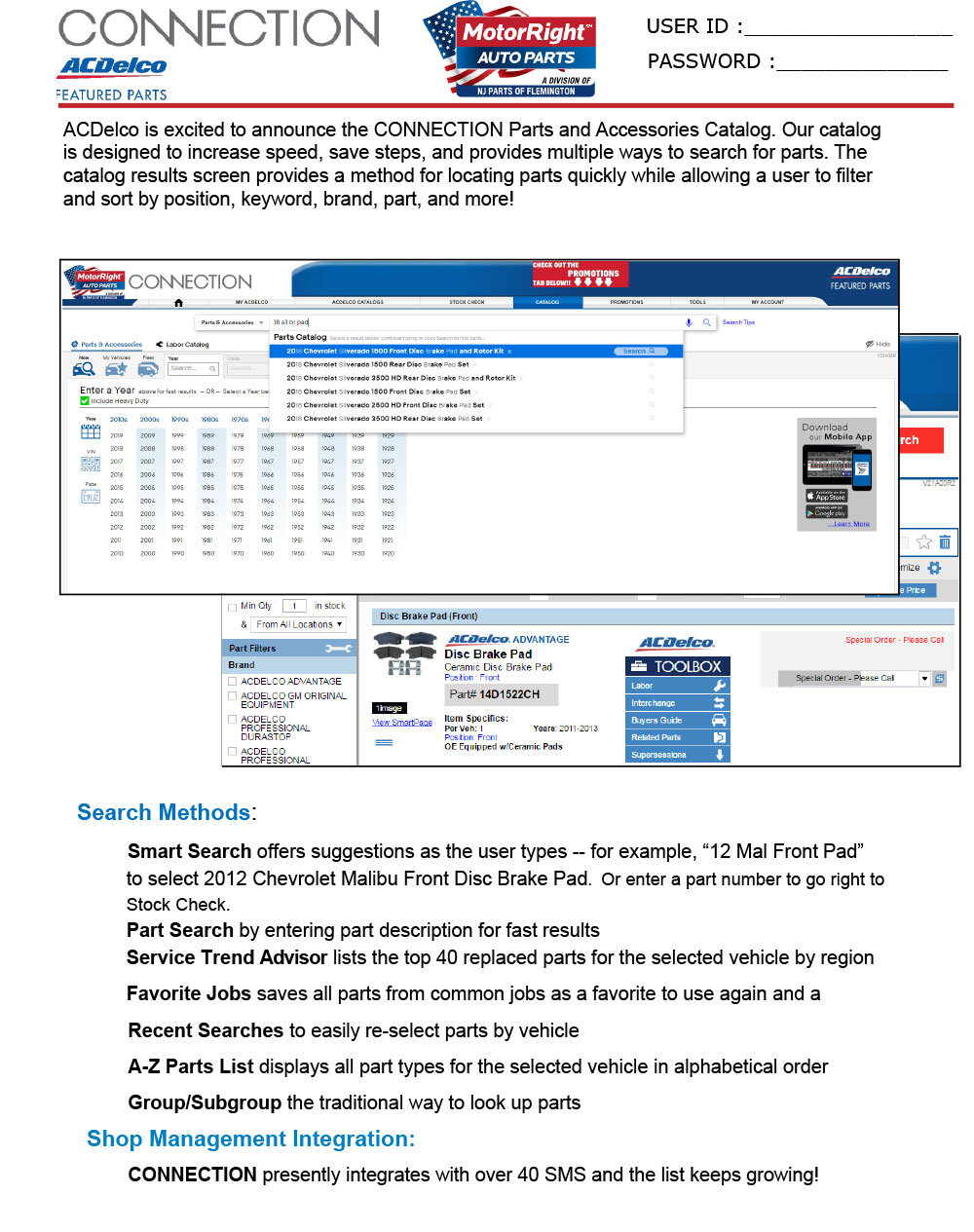

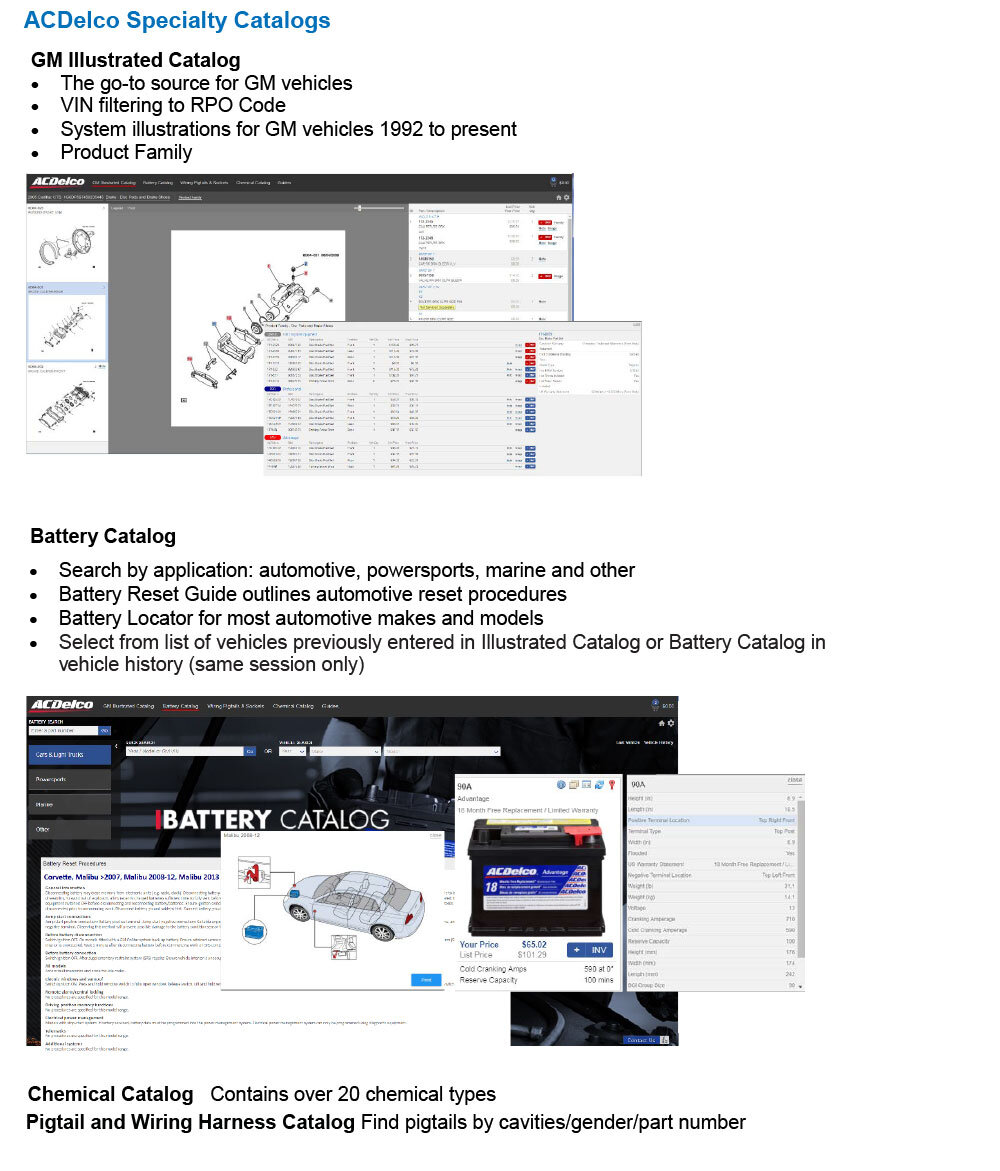

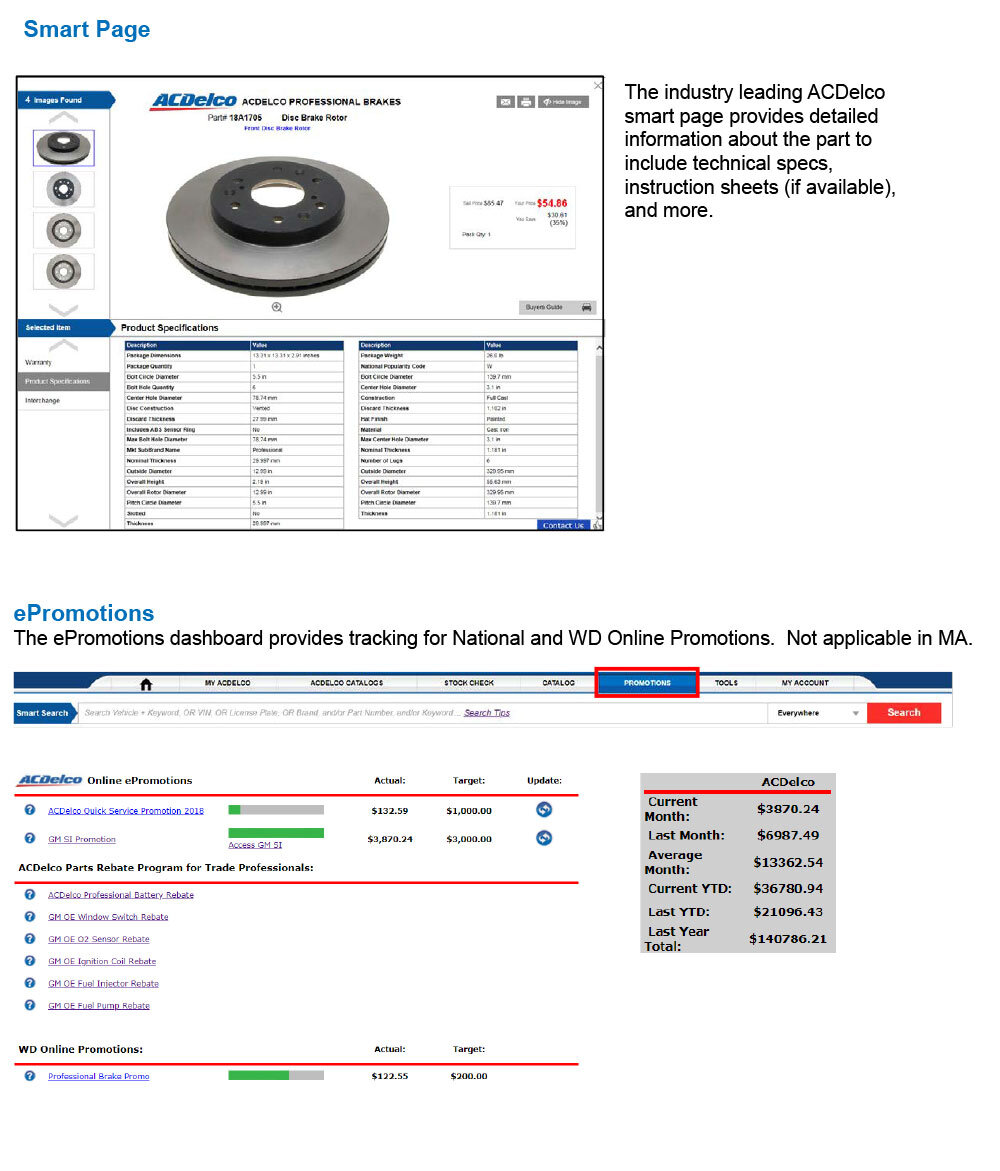

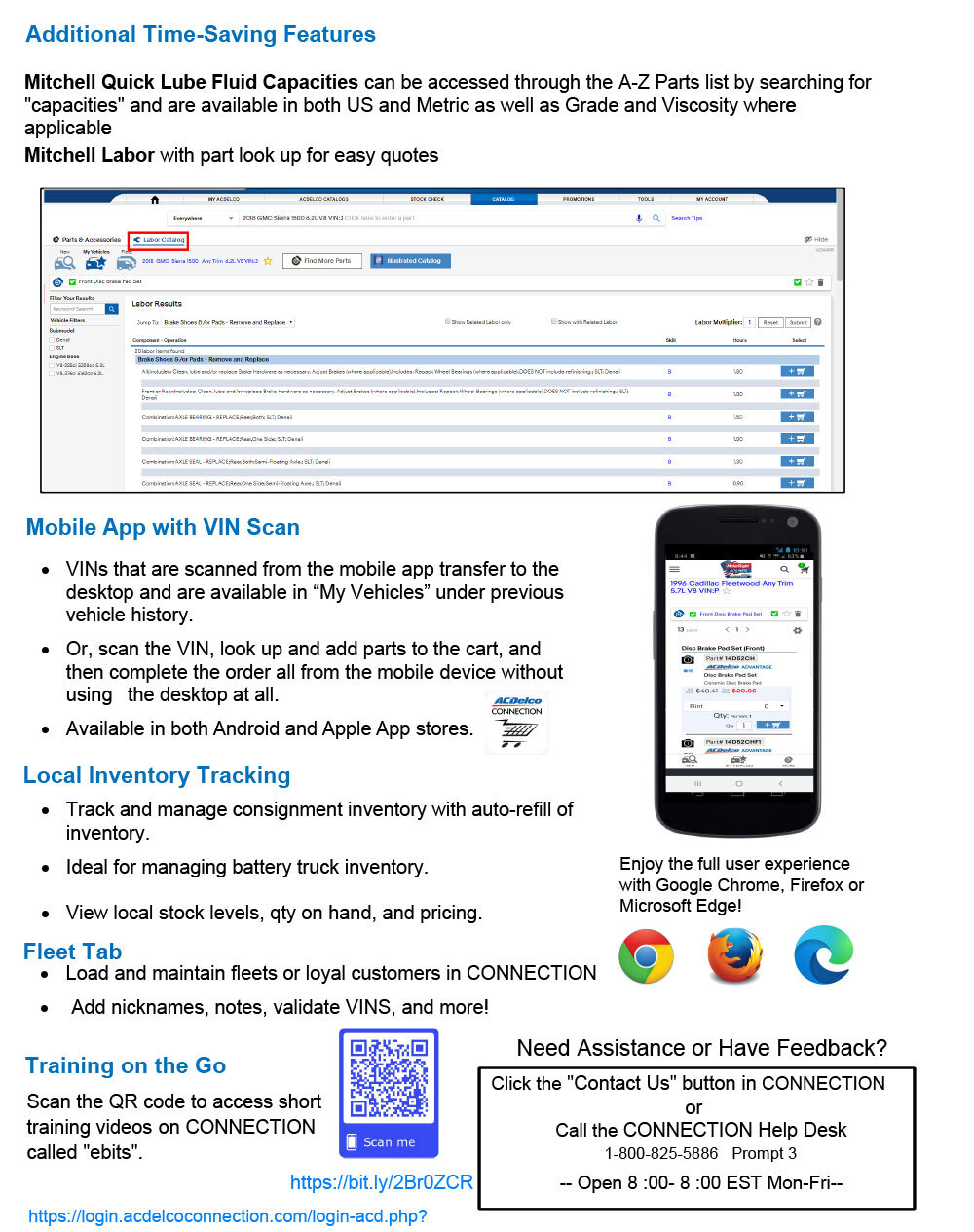

ACDelco announces CONNECTION Parts & Accessories Catalog

Genuine Volkswagen Mechanical Parts via RepairLink

Join INFINITI Parts Rewards

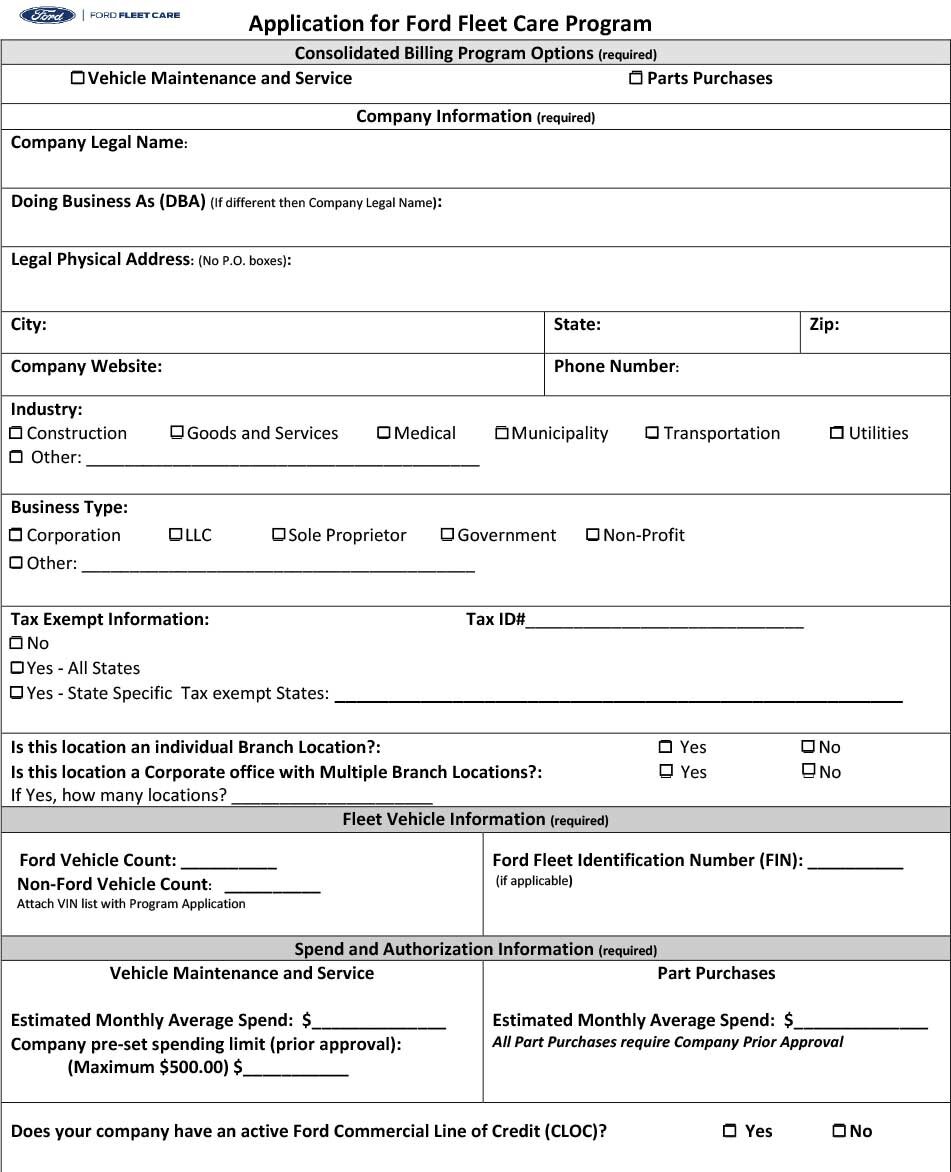

Program Application for Ford Fleet Care Programs

Our Supplier, DFC Introduces Tesla Model S and Model X Brake Rotors & Pads

CERRITOS, CA – California based, Dynamic Friction Company (DFC) announced that Tesla Model S (2012-2019) and Model X (2016-2019) brake components have been added to the DFC premium brake offering. The new part number additions have been made available in DFC’s premium rotor, friction, and hardware line.

DFC’s GeoSpec Coated brake rotor offering has been engineered to precise specifications in order to mimic the Tesla factory components. All DFC GeoSpec Coated brake rotors are specially coated to form a durable and attractive silver-gray finish that fights rust. Each rotor is prepared with a non-directional finish to promote a faster and more even brake pad bed-in, along with quieter and smoother stops.

The combination of DFC’s GeoSpec Coated brake rotors along with the 5000 Advanced application specific formulated brake pads and hardware kit, serves to ensure that braking characteristics maintain factory performance and feel. “We fully acknowledge that the technology behind the advanced braking systems of Tesla require advanced attention to detail in every aspect of its design and have gone the extra mile to ensure that our research and development teams strictly follow the original design,” says DFC Co-Founder, Dino Crescentini.