Ford Provides Details on Sectioning Repair Options

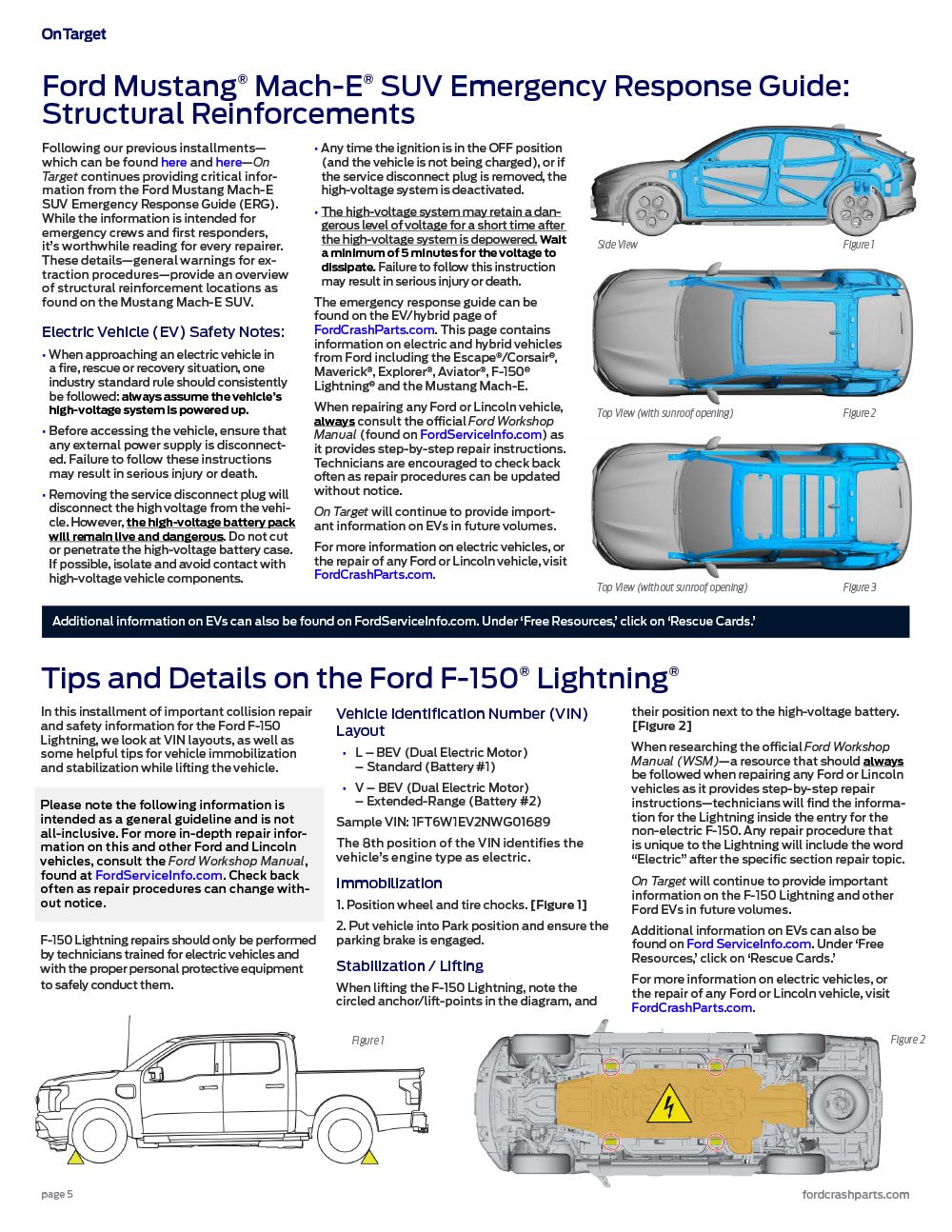

Researching collision repair procedures and mapping out a full repair plan before work begins is not only a great rule of thumb and a good foundation to providing a proper repair, but it is also the key piece of advice that Gerry Bonanni, senior damageability engineer for Ford Motor Company, has always stood by.

“Researching the repair ahead of time will make for a much more efficient repair. There is a huge benefit to knowing what you need to do ahead of time and taking the time to do it right,” said Bonanni.

Gerry Bonanni, Senior Engineer Bonanni reiterated that position in his recent appearance in an episode of I-CAR®’s Repairers Realm video series, where he joined I-CAR technicians Scott VanHulle and Jason Hauboldt to discuss Ford sectioning options, using a pre-recorded video of a cab corner repair on a Ford F-150®.

The video noted the first step of the repair is to prepare the vehicle, which includes protecting elements of the vehicle not included in the repair, such as the fixed glass. The discussion then focused on the best places to cut to section.

“It’s important to note that the sectioning cut-lines provided in the of-ficial Ford Workshop Manual are suggestions,” said Bonanni. “As long as you stay 50 millimeters away from striker or hinge points, which is an industry standard, the best place to cut on exterior components is left up to the technician’s skill level and the type of damage on the vehicle.”

The video points out that drilling rivets to remove them is not easy and that pressing them out with proper, Ford-approved tools—such as a self-piercing rivet (SPR) gun—works better. Another tip provided when using an SPR gun is to ensure it is flush against the rivet, and to not angle it or force it into position as it could snap the die. [Download to Read More]

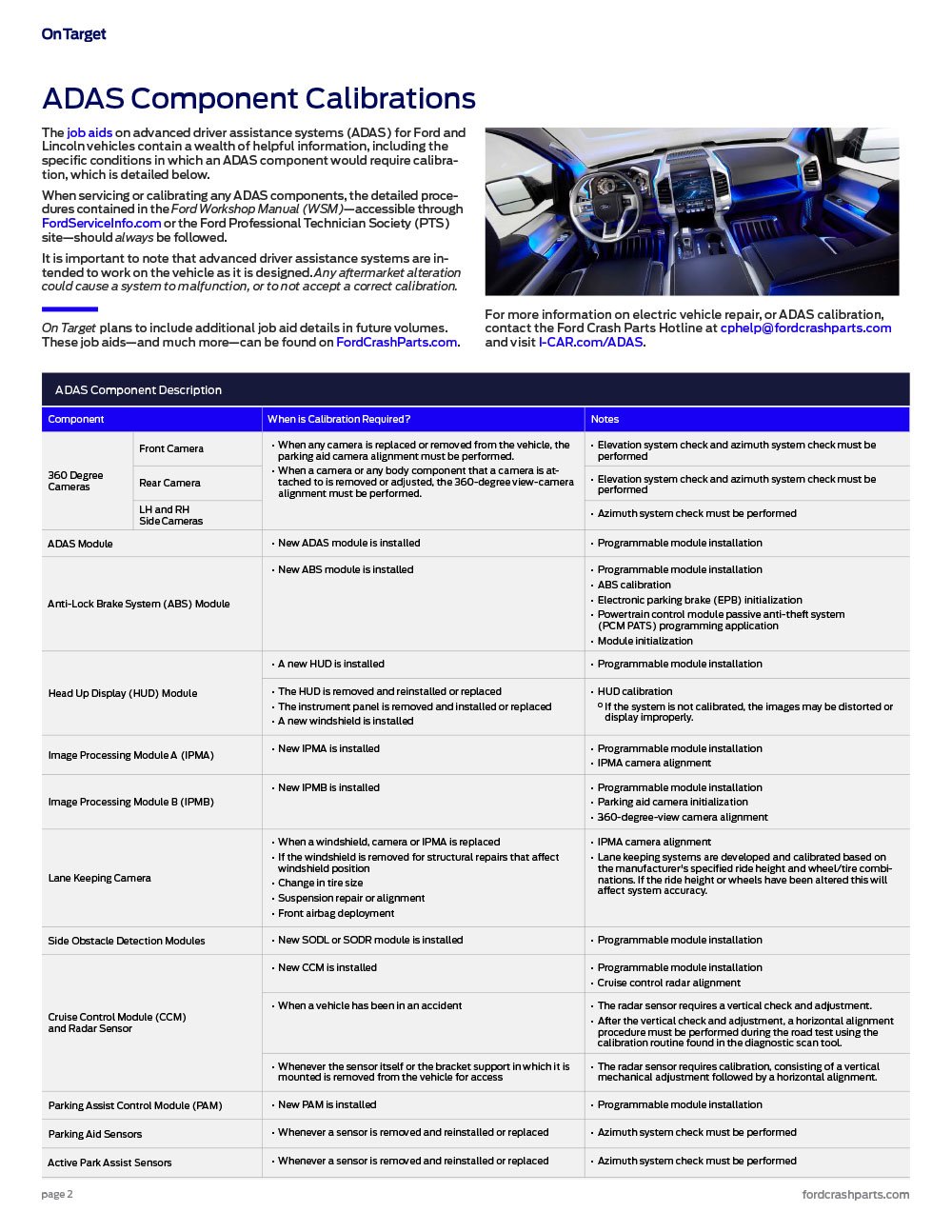

ADAS Component Calibrations

The job aids on advanced driver assistance systems (ADAS) for Ford and Lincoln vehicles contain a wealth of helpful information, including the specific conditions in which an ADAS component would require calibration, which is detailed below.

When servicing or calibrating any ADAS components, the detailed procedures contained in the Ford Workshop Manual (WSM)—accessible through FordServiceInfo.com or the Ford Professional Technician Society (PTS) site—should always be followed.

It is important to note that advanced driver assistance systems are intended to work on the vehicle as it is designed. Any aftermarket alteration could cause a system to malfunction, or to not accept a correct calibration. [Download to Read More]

The Crash Parts Corner

DID YOU KNOW THAT…

A recent I-CAR® Repairers Realm video covered the importance of OEM replacement glass components, as well as the proper tools, equipment and procedures for installing them?

The video—which can also be found at FordCrashParts.com—was hosted by I-CAR technicians Scott VanHulle and Scott Kaboos, who welcomed glass experts from various automakers, including Tim Siterlet, Regional Sales Manager for Carlex Glass America, LLC, the manufacturer and distributor of OEM replacement glass for Ford and Lincoln vehicles.

“Glass has evolved technologically,” said Siterlet, when asked why OEM glass is such a big deal. “OEM parts are designed and engineered, manufactured and tested to the highest quality, government standards. In fact, OE parts must also meet additional federal motor vehicle safety standards. Today’s original equipment glass are performance parts for the vehicle. They enhance your driving experience, your comfort levels and can increase the safe levels of operation when combined with the advanced driver assist features.”

Siterlet noted that many, if not all, glass components are patent-protected, meaning that none of the important vehicle-specific part information—including optical quality, curvature, shape, thickness and other details—are shared with the aftermarket. [Download to Read More]